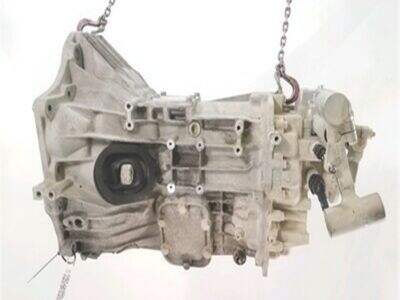

Convitex fleet maintenance providers rely on Gearbox vibration analysis tools. Analyses with these tools identify problems with gearbox components before they escalate into major problems. So, let’s find out why MUST-HAVE tools every fleet maintenance provider should have.

Gearbox Vibration Analysis Tools: Why They Matter

Gearbox Vibration analysis tools are very important for fleet maintenance providers that help identify any hidden problems in the gearbox before it becomes extensive damage. Frequent use of these tools helps maintenance providers spot issues early on and prevent costly repair or replacement. This saves money as well as makes the fleet run smoothly.”

Purchasing Gearbox Vibration Analysis Equipment

Opting for gearbox vibration monitoring devices is a wise step for all fleet maintenance providers. They are User-friendly and the results produced are accurate. Having the tools to check vibration problems in gearboxes and correct them readily available to maintenance providers is what makes such quick checks possible. At its core, a proactive strategy ensures fleet vehicles stay healthy and in good running condition.

HIGHLIGHT OF VIBRATION ANALYSIS TOOLS FOR EARLY DETECTION

One of the main advantages of utilizing gearbox vibration analysis tools is discovering issues in their initial stages. When problems are identified early, maintenance providers can prevent breakdowns and limit downtime. Ensuring that the fleet vehicles are always in good condition and always at the ready. Early detection also increases the lifespan of gearboxes and other components.

Using Gearbox Vibration Analysis Technology

Gearbox vibration analysis technology is rapidly evolving and facilitating accurate failure detection for providers. The advanced features of these tools help in getting precise information with regard to the health of the gear boxes. Maintenance providers can therefore take smart decisions for maintenance and repair using this technology which will result in cost cutting and improved efficiency.

A Vital Tool For Maintenance Providers – Vibration Analysis Tools

It conveys the importance of Gearbox vibration analysis tools to maintenance providers. They are required in order to locate gearbox issues efficiently and accurately. And this way, maintenance providers will be able to anticipate potential problems and ensure that the fleet vehicles are properly maintained.Editor's note. Maintenance providers can deliver great services to clients and earn a strong reputation in the industry with vibration analysis tools.

To sum it all up, gearbox vibration analysis tools are more of a requirement than a luxury for every fleet maintenance provider and Convitex is no different. These tools help to identify problems early and also save money and improve efficiency. With this, maintenance providers can give smooth running fleet vehicles and fantastic services to their customers.

EN

EN